Appendix 1-12-2 Ship Construction File Form Example

Ship Construction File

M / V | " " |

IMO No.: | |

Hull No.: |

Shipbuilder :

Guidance Relating to the Rules for the Classification of Steel Ships 2015 265

Pt 1 Classification and Surveys

Appendix 1-12-2 Ship Construction File Form Example Pt 1, Appendix 1-12-2

![]()

The shipbuilder is to deliver documents for the Ship Construction File. In the event that items have been provided by another party such as the shipowner and where separate arrangements have been made for document delivery which excludes the shipbuilder, that party has the responsibility.

It is recognized that the purpose of documents held in the Ship Construction File on board the ship, is to fa cilitate inspection(survey) and repair and m aintenance, and therefore, is to include but not to limited to:

266 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Appendix 1-12-2 Ship Construction File Form Example Pt 1, Appendix 1-12-2

![]()

1. Final Drawings:

As-built structural drawings including scantling details, material details, and, as applicable, wastage allowances, location of butts and seams, cross section details and locations of all partial and full penetration welds, areas identified for close attention(for general dry cargo ships, liquefied gas carriers and ships subject to the enhanced survey programme) and rudders

And the followings are to be included.

(1) Approved plans of critical areas if applicable

(2) Hatch cover structural drawings and details if applicable (3) Rudder structural drawings and details

(4) Freeboard marks and draft marks details (5) Principal dimensions details

List of Final Drawings

Serial No. | DWG No. | Title of DWG | DWG Box No. |

Guidance Relating to the Rules for the Classification of Steel Ships 2015 267

![]()

Pt 1 Classification and Surveys

Appendix 1-12-2 Ship Construction File Form Example Pt 1, Appendix 1-12-2

![]()

2. Manuals required for classification and statutory requirements, e.g. loading and stability, bow doors and inner doors and side shell doors and stern doors – operations and maintenance manuals(IACS UR S8(Bow Doors and Inner Doors) and S9(Side Shell Doors and Stern Doors)), including ship structures access manual, as applicable.

List of Manuals

Serial No. | Manual No. | Title of Manual | Manual Box No. |

268 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Appendix 1-12-2 Ship Construction File Form Example Pt 1, Appendix 1-12-2

![]()

3. Copies of certificates of forgings and castings welded into the hull(IACS UR W7(Hull and Machinery Steel Forging) and W8(Hull and Machinery Steel Casting))

List of Copies of Certificates

Serial No. | Cert. No. | Title of Certificate | Remarks |

(Note: Copies of Certificates are attached)

Guidance Relating to the Rules for the Classification of Steel Ships 2015 269

![]()

Pt 1 Classification and Surveys

Appendix 1-12-2 Ship Construction File Form Example Pt 1, Appendix 1-12-2

![]()

4. Details of equipment forming part of the watertight and weather tight integrity of the ship(e.g. overboard discharges, air pipes, ventilators)

List of Drawings or Copies of Certificates

Serial No. | DWG/Cert. No. | Title of DWG/Certificate | Box No. |

(Note: Details(drawings, copies of certificates, etc.) of the relevant equipments are attached, or kept at specified box)

270 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Appendix 1-12-2 Ship Construction File Form Example Pt 1, Appendix 1-12-2

![]()

5. Tank testing plan including details of the test requirements(IACS UR S14(Testing Procedures of Watertight Compartments))

6. Corrosion prevention specifications(IACS UR Z8(Corrosion Protection Coating for Salt Water Ballast Spaces) and Z9(Corrosion Protection Coatings for Cargo Hold Spaces on Bulk Carriers))

7. Details for the in-water survey, if applicable, information for divers, clearances measurements instructions etc., tank and compartment boundaries.

8. Docking plan and details of all penetrations normally examined at drydocking.

9. Coating Technical File, for ships subject to com pliance with the IM O Performance Standard for Protective Coatings(PSPC) as a class requirement under the IACS Common Structural Rules.

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 271

Pt 1 Classification and Surveys

Annex 1-13 Owner's Hull Inspection and Maintenance Program Pt 1, Annex 1-13

![]()

Annex 1-13 Owner's Hull Inspection and Maintenance Program

1. General

(1) The Owner's Hull Inspection and Maintenance Program is recommended as an assistant means for maintaining compliance with classification requirements between periodical surveys of the Society by means of owner's inspection and maintenance for the hull structure and corrosion prevention system on a regular basis. This program will not substitute the periodical survey to maintain the classification.

(2) This program can be applied to all type of ships at the request of the Owners. However, when an existing ship applies to enter the program, this program can be applied where deemed appro- priate by the Society considering survey history, damage history and coating conditions, etc.

(3) The OHIMP notation shall be assigned as an additional special feature notation to ship comply with this Owner's Hull Inspection and Maintenance Program.

(4) The OHIMP notation and the application of this program may be cancelled by the Society if the program is not being satisfactorily carried out, should either the maintenance records or the

general condition of the hull structure be determined to be unacceptable.

(5) In the case of a change of Owner, the application of this program is to be reconsidered.

(6) This program may be supported and maintained by a computerized system as deemed appro- priate by the Society.

2. Requirements

(1) Outstanding recommendations/conditions of class related to the hull, should be completed prior to the ship being able to participate in this program.

(2) Surveys to maintain the classification are to be up-to-date, and without outstanding recom-

mendations/conditions of class related to the hull structure and corrosion prevention system which would affect this program.

(3) In addition to the regular inspection and maintenance in accordance with the Owner's Hull

Inspection and Maintenance Program, if there is a damage which may affect the classification at hull structure or corrosion prevention system, the occasional or additional inspections and main- tenance are to be carried out and the damage is to be examined by the Society at the first port

of call. If it necessary the voyage repairs are to be carried out in accordance with Ch 2, 107.

5 of the Rules. The relevant details are to be recorded in the Owner's Hull Inspection and Maintenance Program as part of the report.

3. Approval and survey

(1) Documents and approval

The Owner is to submit a comprehensive Owner's Hull Inspection and Maintenance Program

manual, which is to include the followings, to the Society. The Society will issue an approval certificate for the Owner's Hull Inspection and Maintenance Program after review the presented documents.

(A) Safety policy and enclosed space entry procedures of the company.(For information only)

(B) General Arrangement

(C) Midship Section

(D) Complete list of each spaces and areas,(i.e., cargo holds, cargo tanks, ballast tanks, void spaces, cofferdams, pipe tunnels, etc.) covered by the Owner's Hull Inspection and Maintenance Program.

(E) Details of any corrosion prevention system and coating condition for each of the space and area specified in (D) above

(F) Inspection intervals corresponding to each space and area, or group of space and areas

(G) Maintenance descriptions detailing the minimum work necessary for the satisfactory in- spection of the each space and area

272 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-13 Owner's Hull Inspection and Maintenance Program Pt 1, Annex 1-13

![]()

(H) Sample reports and reporting procedures to confirm that the Owner's Hull Inspection and Maintenance Program is working properly onboard. There is to be a system for reporting the following information to the Owners office and for recording onboard;

(a) Details of the inspections carried out(details are to include proper structure identification such as tank/hold information, frame number, deck, shell plating, stringers, bulkheads and longitudinals as identified on the ship's drawings)

(b)

(c)

The conditions as found

Any findings, repairs or maintenance undertaken

(I) Selection of designated inspector that conduct the inspection, including name, title and date of last related training

(J) Training information on inspector to carry out these inspection

(K) Other documentations as deemed necessary by the Society

(2) Implementation survey

(A) The implementation survey is to be carried out within one year from the date of the appro-

val of the Owner's Hull Inspection and Maintenance Program to verify that the approval of Owner's Hull Inspection and Maintenance Program is valid onboard.

(B) During the implementation survey, the attending Surveyor is to check the following items.

(a)

(b)

(c)

(d)

(3) Annual

An approval certificate for the Owner's Hull Inspection and Maintenance Program Documents specified in (1)

Whether the Master and designated inspectors are familiar with the Owner's Hull

Inspection and Maintenance Program

Check whether the Owner's Hull Inspection and Maintenance Program is operated satisfactorily.

audit

(A) An annual audit is to be carried out to check the operation of the Owner's Hull Inspection and Maintenance Program at Annual Survey

(B) At the annual audit the attending Surveyor is to check the following items.

(a)

(b)

(c)

(d)

(e)

(f)

(g)

An approval certificate for the Owner's Hull Inspection and Maintenance Program Reviewed Owner's Hull Inspection and Maintenance Program manual

Whether the Master and designated inspectors are familiar with the Owner's Hull

Inspection and Maintenance Program Ship's survey status and history

The Owner's Hull Inspection and Maintenance Program information is being updated and

the planned inspections are being carried and reported upon by a inspector responsible for maintaining the detail of the program as required

General review of the Owner's Hull Inspection and Maintenance Program inspections ac-

complished within the previous year is to be carried out

If the inspection report(s) indicate damages or other defects that affect or may affect

classification, then the affected area is to be examined.

4. Inspector training

(1) The ship's designated inspector that will be carrying out the inspections for the Owner's Hull Inspection and Maintenance Program is to undergo training as deemed appropriate by the

Society prior to being accepted as inspector for this program. However, is designated as the inspector it may considered as if he had undergone

(2) The training can be done either internally or externally as decided by

if the navigation officer the training already.

the Owner. As a mini-

mum, the training program is to include topics such as means of access, coating evaluation, ter-

minology of ship structure, classification survey, typical hull defects and/or critical structural areas associated with the ship type, acceptance and evaluation criteria, reporting, etc. ![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 273

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

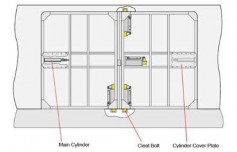

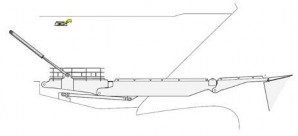

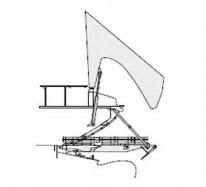

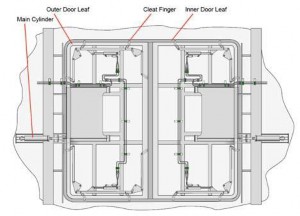

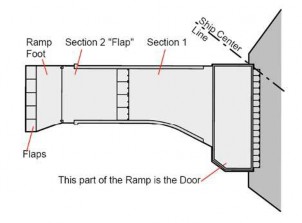

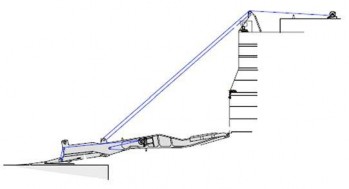

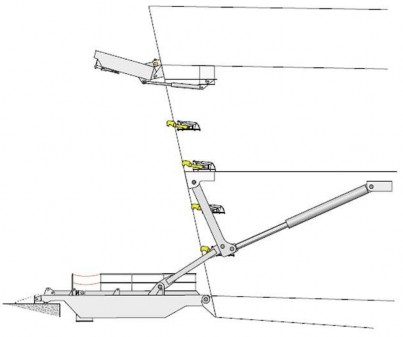

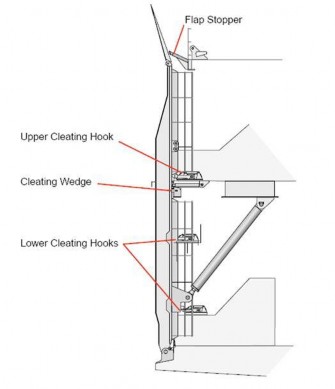

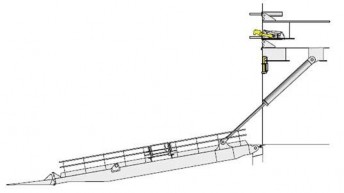

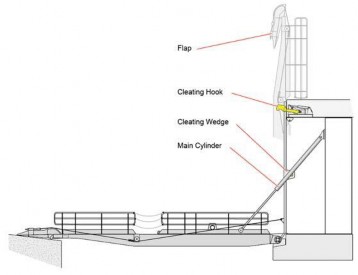

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors

Typical examples of bow, inner, side shell and stern doors specified in Ch 2, Sec 16

may be illustrated as follows.

of the Rules

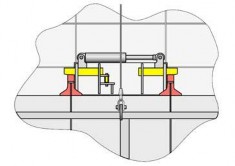

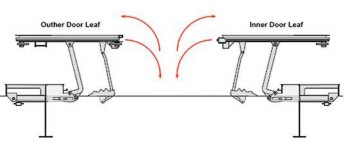

1. Inner Bow Doors - double leaf side hinged

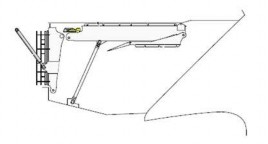

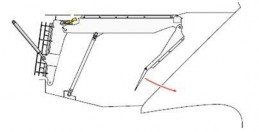

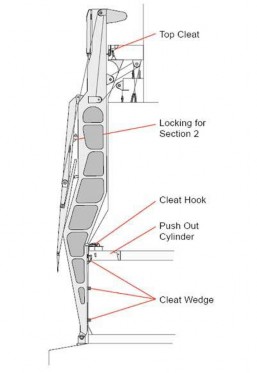

2. Bow Loading Ramp - stowed position, aft part (inner door) disconnected

3. Bow Loading Ramp - beginning of opening sequence, hinge pin

aft part (inner door) connected by hydraulic

4. Bow Loading Ramp - ramp partly extended to quay

274 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

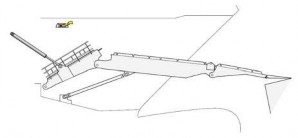

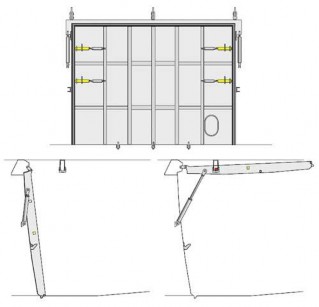

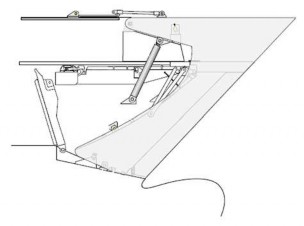

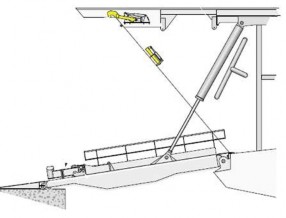

5. Bow Loading Ramp - ramp fully extended to quay

6. Inner Bow Door - single leaf top hinged, type 1

7. Inner Bow Door - single leaf top hinged, type 2

Guidance Relating to the Rules for the Classification of Steel Ships 2015 275

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

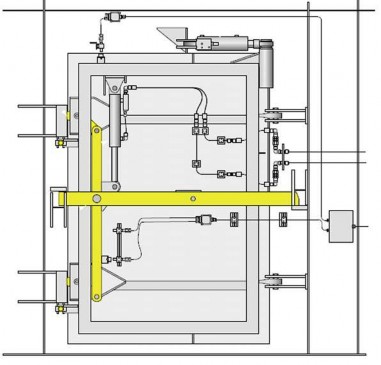

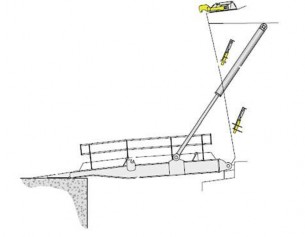

8. Bow Loading Ramp - side opening bow doors

9. Bow side opening door - closed, side view

10.

Bow side opening door - closed, top view

11. Bow side opening door - door panel details

276 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

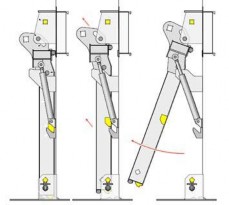

12.

13.

Bow side opening door - open, top view

Bow Loading Ramp - visor type bow doors, general arrangement

14. Bow Visor Door - general arrangement

Guidance Relating to the Rules for the Classification of Steel Ships 2015 277

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

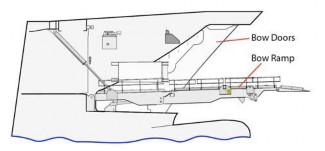

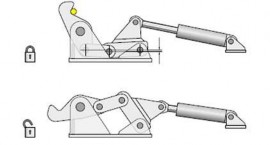

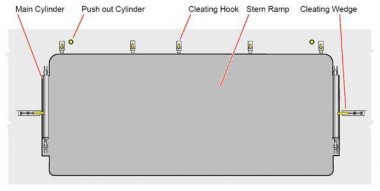

15.

Cleating Hook 1

16. Cleating Hook 2

17. Cleating Wedge

278 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

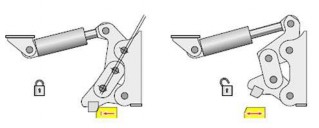

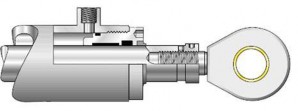

18.

Hydraulic Actuators 1

19. Hydraulic Actuators 2

20.

Hydraulic Actuators 3

21. Hydraulic Actuators 4

22. Control Panel - closing door

Guidance Relating to the Rules for the Classification of Steel Ships 2015 279

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

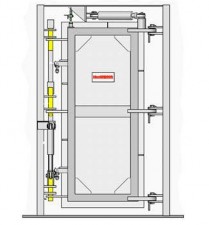

23.

24.

Bunker Door - closed, inside view

Bunker Door - Emergency Cleat

25. Bunker Port - type 1, closed, inside view

26. Bunker Port - type 2, closed, inside view

280 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

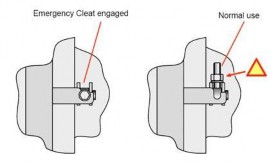

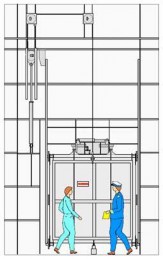

27.

Cargo Door - closed, inside

28. Cargo Door - open, inside

29. Cargo Door - principle function

Guidance Relating to the Rules for the Classification of Steel Ships 2015 281

Pt 1 Classification and Surveys

![]()

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

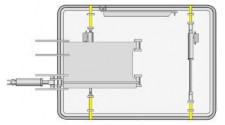

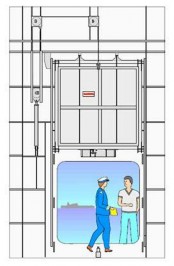

30.

Cargo Door - top side hydraulic securing device disengaged

31. Cargo Door - top side hydraulic securing device engaged

282 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

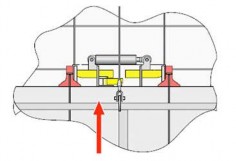

32.

33.

Side Shell Door - double leaf, closed, inside view

Side Shell Door - double leaf, closed, top view

34. Side Shell Door - double leaf, fully opened, top view

35.

Side Shell Door - double leaf, half opened, top view

Guidance Relating to the Rules for the Classification of Steel Ships 2015 283

Pt 1 Classification and Surveys

![]()

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

36.

37.

Pilot Door - inside view

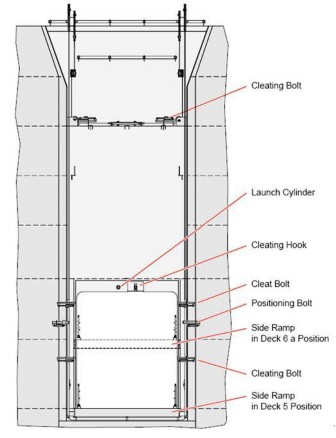

Side Ramp - front view

284 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

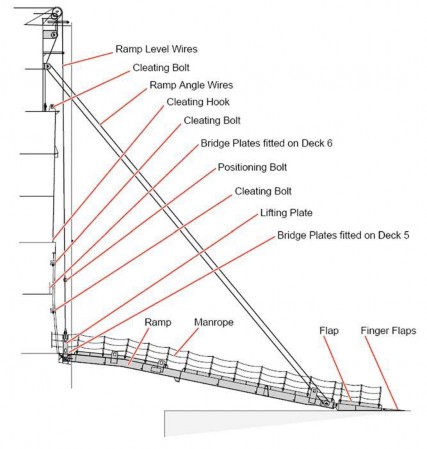

38. Side Ramp - side view

39. Side Ramp - top view

Guidance Relating to the Rules for the Classification of Steel Ships 2015 285

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

40.

41.

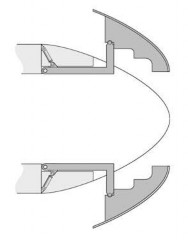

Stern Door - single leaf, closed, car carrier type

Stern Door - single leaf, open, car carrier type, top view

42. Stern Door - single leaf, open, car carrier type

286 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

43.

Stern Door - double leaf, open, typical cleating arrangement

44. Stern Door - single leaf, open typical cleating arrangement, type 1

45.

Stern Door - single leaf, open, typical cleating arrangement, type 2

Guidance Relating to the Rules for the Classification of Steel Ships 2015 287

Pt 1 Classification and Surveys

![]()

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

46.

Stern Door - single leaf, closed, inside view, typical cleating arrangement, type 3

47. Stern Door - single leaf, closed, typical cleating arrangement, type 3

48.

Stern Door - single leaf, open, push-out cylinder arrangement

288 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-14 Examples of Typical Bow, Inner, Side Shell and Stern Doors Pt 1, Annex 1-14

![]()

49. Stern Door - single leaf, open, typical cleating arrangement, type 3

Guidance Relating to the Rules for the Classification of Steel Ships 2015 289

Pt 1 Classification and Surveys

Annex 1-15 Requirements for CLEAN Notation Pt 1, Annex 1-15

![]()

Annex 1-15 Requirements for CLEAN Notation

1. General

(1) This Annex applies to the ships classed with the Society or intended to be registered under the Society, which intended to comply with the environmental protection requirements for design, construction and operation for obtaining the relevant notation.

(2) The notation prescribed in (1) are classified into the followings.

(A) CLEAN1 notation: Ships complying with requirements of convention specified in Par 3

(B) CLEAN2 notation: Ships complying with additional requirements of the Society specified in

Par 4

(C) CLEAN3 notation: Ships complying with additional requirements in Par 5

2. Survey

(1) Classification survey

(A) The documents specified in applicable requirements for each notation are to be submitted to the Society.

(B) The appropriate installation of all relevant equipment specified in applicable requirements for

each notation and the proper provision on board of all relevant documents, procedures and record books are to be confirmed.

(2) Periodical survey

(A) The periodical surveys to maintain the classification are to be carried out at Annual Survey, Intermediate Survey and Special Survey. However, the survey for MARPOL Annex IV and

V is to be carried out at Special Survey and the periodical survey for AFS convention is

not required.

(B) The satisfactory condition of all relevant equipment specified in applicable requirements for

each notation and proper maintaining of all relevant documents, procedures and record books are to be confirmed.

3. CLEAN1 notation

For obtaining CLEAN1 notation, the ship is to be in compliance with applicable requirements of MARPOL Annex I, II, IV, V and VI and AFS convention.

4. CLEAN2 notation

For obtaining CLEAN2 notation, the ship is to be in compliance with documents requirements of

Table 1 and applicable requirements of Table 3 for applicable convention in addition to Par 3.

5. CLEAN3 notation

For obtaining CLEAN3 notation, the ship is to be in compliance with additional documents require- ments of Table 2 and additional requirements of Table 4 in addition to Par 4.

290 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-15 Requirements for CLEAN Notation Pt 1, Annex 1-15

![]()

Table 1 Documentation requirements for CLEAN2 notation

Items | Plans and documents to be submitted | Certificate/ Statement of Compliance | ||

For approval | For review | |||

Marine pollution prevention | Oil (related to MARPOL Annex I) | Arrangement for cargo and oil loading and discharge manifold, including drip trays and drainage systems | (1) Bunkering procedures (2) Bilge water management plan | IOPP Certificate |

Noxious Liquid Substances (related to MARPOL Annex II) | Arrangement for cargo and oil loading and discharge manifold, including drip trays and drainage systems | NLS Certificate or IBC/BCH Statement of Compliance | ||

Sewage (related to MARPOL Annex IV) | Sewage management plan | ISPP Certificate or Statement of Compliance | ||

Garbage (related to MARPOL Annex V) | Garbage management plan | |||

Air pollution prevention | Emission to air (related to MARPOL Annex VI) | Piping diagram for refrigeration and air conditioning systems | (1) Fuel oil management plan (2) Ozone depleting substances management procedure, if necessary | IAPP Certificate |

Energy Efficiency (related to MARPOL Annex VI) | IEE Certificate/ Statement of Compliance | |||

Preventing destruction of the ecosystem | Anti-Fouling Systems (related to AFS Convention) | Biofouling management plan | IAFS Certificate/ Statement of Compliance | |

Ballast water management (related to BWM Convention) | IIHM Certificate/ Statement of Compliance | |||

Ship recycling | Ship recycling (related to Ship Recycling Convention) | IIHM Certificate/ Statement of Compliance | ||

Safety management system | Safety management system (related to ISM Code) | SMC | ||

Table 2 Additional documentation requirements for CLEAN3 notation

Items | Plans and documents to be submitted | Certificate/ Statement of Compliance | ||

For approval | For review | |||

Marine pollution prevention | Oil | Arrangements of tanks which are to be protected in accordance with Par 2 of Oil item in Table 4 | Type approval certificate of oil filtering equipment in accordance with Par 1 of Oil item in Table 4 | |

Air pollution prevention | Emission to air | Type approval certificate of incinerator in accordance with Par 3 of Emission to air item in Table 4 | ||

Guidance Relating to the Rules for the Classification of Steel Ships 2015 291

![]()

Pt 1 Classification and Surveys

Annex 1-15 Requirements for CLEAN Notation Pt 1, Annex 1-15

![]()

![]()

![]()

![]()

Table 3 Requirements for CLEAN2 notation

Items | Requirements | |

Marine pollution prevention | Oil | 1. For machinery spaces, the following requirements are to be complied with: (1) Fuel oil tanks, lubricating oil tanks and other oil tanks, which are mechanically filled by pumps, etc., are to be equipped with high level alarm to prevent overfilling. (2) Oil filtering equipment for machinery spaces is to be provided with arrangements to ensure that any discharge of oily mixtures is automatically stopped in cases where the oil content of effluents exceeds 15 . (3) Drip trays with capacities of at least the following are to be fitted under all vents and filling manifolds for fuel oil tanks, lubricating oil tanks, other oil tanks: (A) for vessels less than 1600 gross tonnage: 80 (B) for vessels equal to or larger than 1600 gross tonnage: 160 (4) Bilge water management plan is to be place onboard. This plan is to include the following. (A) Vessel name and class number (B) Type and size of vessel (C) Bilge water treatment procedure and system arrangement 2. For cargo area of oil tankers, the following requirements are to be complied with: (1) Each cargo tank is to be fitted with a high level alarm and an overfill alarm, and the overfill alarm is to be independent of the tank gauging system. (2) All cargo manifolds are to be fitted with drip trays with means for drainage to a appropriate tank onboard. The drip trays is to have the following capacities: - length: beyond forward and aft ends of the manifold - width: at least 1800 , though such that the spill tray extends at least 1200 outboard of the end of the manifold flange - depth: minimum depth 300 (3) Coamings are to be fitted on deck in accordance with Pt 8, Ch 2, 104. 1 (6) of the Rules. (4) Requirements in Pt 7, Ch 1, 1002. 7 (4) of the Rules are to be complied with. 3. Ships are to be classed with Emergency Response Service System of the Society or any society which is subject to verification of compliance with QSCS(Quality System Certification Scheme) of IACS. |

Noxious Liquid Substances | 1. NLS tankers defined in MARPOL Annex II/16.9 are to be comply with the following requirements. (1) All cargo manifolds are to be fitted with drip trays with means for drainage to a appropriate tank onboard. The drip trays is to have the following capacities: - length: beyond forward and aft ends of the manifold - width: at least 1800 , though such that the spill tray extends at least 1200 outboard of the end of the manifold flange - depth: minimum depth 300 (2) Coamings are to be fitted on deck in accordance with Pt 7, Ch 6, 307. 7 of the Rules. (4) Piping systems serving permanent ballast tanks are to be independent of piping systems serving cargo tanks and of cargo tanks themselves in accordance with Pt 7, Ch 6, 305. 1 of the Rules. | |

Sewage | 1. Sewage system ventilation pipes are to be independent from other ventilation piping systems. 2. A sewage management plan is to be placed onboard. This plan is to include the following. (1) Vessel name and class number (2) Diagrams and component description of the sewage system (3) Instructions for the operation and management of the sewage system 3. The recorded data shall include, as a minimum, date of discharge; quantity of sewage discharge; location and type of reception facility; and for sea discharges, the distance to the nearest land and the vessel’s speed. | |

Garbage | A garbage management plan in accordance with IMO Res.MEPC.220(63) is to be placed onboard. | |

![]()

![]()

292 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-15 Requirements for CLEAN Notation Pt 1, Annex 1-15

![]()

![]()

![]()

Table 3 Requirements for CLEAN2 notation (Continued)

Items | Requirements | |

Air pollution prevention | Emission to air | 1. Fuel oil management plan is to be placed onboard. This plan is to include the following. (1) Vessel name and class number (2) fuel oil quality complying with MARPOL) Annex VI/18.3 (3) Those vessels using separate fuels when entering or leaving an ECA are to include in the fuel oil management plan the following: (A) Procedures on how to perform the fuel oil changeover (B) Diagrams of the fuel oil system including details of change over (C) Methods and means of recording volume of low-sulfur fuel oils in tanks, and date, time, and position of the vessel when any operation of fuel oil changeover 2. Refrigerating facilities and air-conditioning equipment using ozone depleting sub- stances are to comply with the following. (1) Annual refrigerant leakage is to be not more than 10% in mass( ) of the total refrigerant charge of each system. (2) At least one gas detector is to be provided to spaces into which the re- frigerant in facilities could leak. The detection is to give an visible and audi- ble alarm in a manned location when the refrigerant concentration exceeds a predetermined limit(for example, 25 for ammonia or 300 (3) For refrigerant recovery, refrigerant compressors are to be capable of evacuat- ing a system charge into an storage container and capacity of this storage container is to be at least 125% of the largest volume of discharged refrigerant. (4) A Ozone depleting substances management procedures is to be placed on- board if necessary. This procedure is to include: (A) Vessel name and class number (B) Diagrams and component description of all refrigerant systems (C) Procedures detailing the means to control the loss, leakage, venting, and disposal of refrigerants (D) Methods and means of recording refrigerant inventory (a) Supply of refrigerant onboard (b) Discharge of refrigerant to the atmosphere due to leaks or system maintenance (c) Recovered refrigerant including its storage location (d) Refrigerant disposal to land-based reception facilities (E) Refrigerants data sheet (F) Specification of fire fighting systems, including data sheet for extinguish- ing media 3. Portable and fixed fire extinguishing systems are not to include halon 1211, 1301, 2402 and perfluorohydrocarbons. 4. Where installed onboard, incinerators are to be type-approved in accordance with IMO Res.MEPC.76(40) or Res.MEPC.244(66) whichever is applicable to the ship. |

Energy Efficiency | An IEE Certificate or Statement of Compliance is to be issued and maintained. | |

Preventing destruction of the ecosystem | Anti-Fouling Systems | A biofouling management plan recommended in IMO Res.MEPC.207(62) is to be placed onboard. |

Ballast water management | An IBWM Certificate or Statement of Compliance is to be issued and maintained. | |

Ship recycling | Ship recycling | An IIHM Certificate or Statement of Compliance is to be issued and maintained. |

Safety management system | Safety management system | A SMC is to be issued and maintained. |

Guidance Relating to the Rules for the Classification of Steel Ships 2015 293

![]()

Pt 1 Classification and Surveys

Annex 1-15 Requirements for CLEAN Notation Pt 1, Annex 1-15

![]()

![]()

![]()

Table 4 Additional requirements for CLEAN3 notation

Items | Requirements | |

Marine pollution prevention | Oil | 1. Oil filtering equipment is to be provided with automatic stopping arrangements are to be provided for any discharge of oily mixtures when the oil content in the ef- fluent exceeds 5 . 2. Lubricating oil tanks and hydraulic oil tanks are to comply with the requirements of MARPOL Annex I/12A. |

Noxious Liquid Substances | 1. NLS tankers defined in MARPOL Annex II/16.9 are to be comply with the follow- ing requirements. (1) The arrangements of cargo tanks are to comply with the double hull and dou- ble bottom requirements of a Type 2 ship specified in Pt 7, Ch 6, 206. 1 (2) of the Rules unless a Type 1 ship is to comply with requirements of a Type 1 ship. (2) Gauging systems for cargo tanks are to be of closed device specified in Pt 7, Ch 6, 1301. 1 (3) of the Rules. | |

Garbage | Ships are not to dispose of food wastes into the sea except when they have been passed through a comminuter or grinder. | |

Air pollution prevention | Emission to air | 1. Refrigerants and Fire-extinguishing Medium used onboard are to be of the following. (1) Ozone depleting potential(ODP) = 0 (2) Global warming potential(GWP) < 2000 2. Tankers carrying crude oil or petroleum product with flash point less than 60 are to have VEC2 notation. 3. At least one incinerator is to be installed onboard and is to be type approved in accordance with IMO Res.MEPC.76(40) or Res.MEPC.244(66). |

![]()

294 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

![]()

PART 1 CLASSIFICATION AND SURVEYS

Published by

NO.5, Shabnam. Alley

Qaem Maqam-e-Farahani St., Haft-e-Tir.

Sqr, TEHRAN, IRAN

TEL : +98 21 421 6000

FAX : +98 21 8832 4734

Website : http://www.ics.org.ir

![]()

CopyrightⒸ 2015, ICS

Reproduction of this Rules and Guidance in whole or in parts is prohibited without permission of the publisher.

![]()